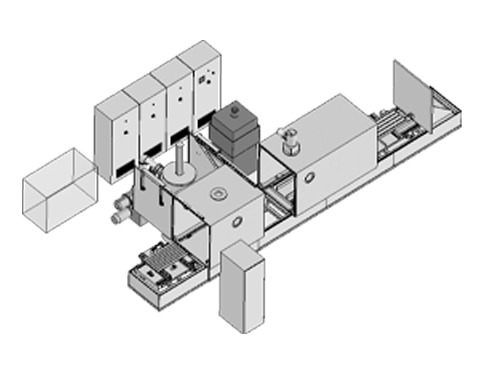

Small and Medium

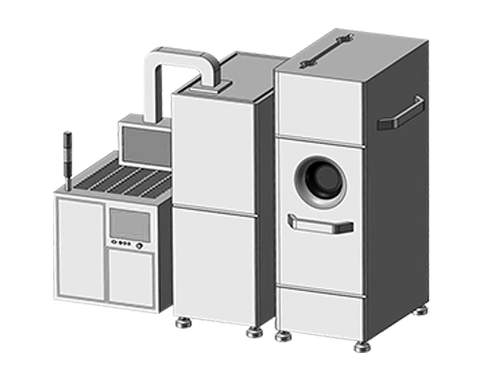

Electron Beam Welding Machines

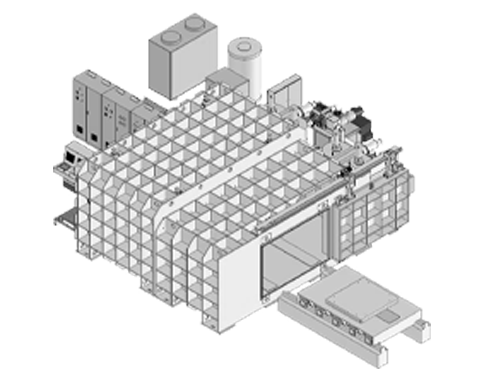

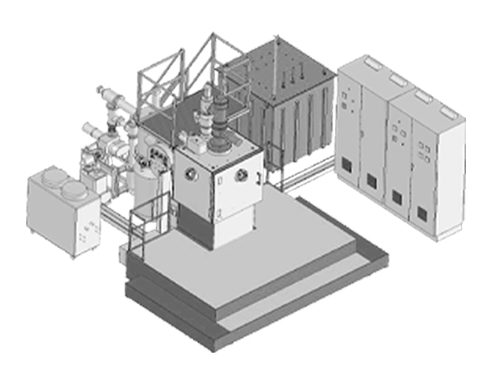

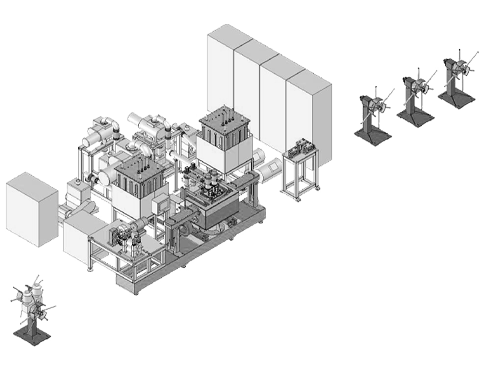

Electron Beam Welding Machines

The electron beam welding utilizes a high-speed moving electrons to impact the workpiece, and kinetic energy convert into thermal energy and melting the workpiece metal to form a weld seam.

Main Components

Electron gun and its power supply system

Vacuum system

Welding chamber

Seam observation system

Worktables

CNC control system

Cooling water circulation system

Power source

Controlling center

Horizontal moving or vertical rotating worktable (optional)

Parameters & Performances

| Series | SEBW(G)60 | SEBW(G)70 | SEBW(G)80 | SEBW(G)90 |

|---|---|---|---|---|

| Accelerating Voltage | 0~60KV | 0~70KV | 0~80KV | 0~90KV |

| Power | 0~15KW | 0~15KW | 0~20KW | 0~25KW |

| Stability of Accelerating Voltage | ±0.2%~±0.3% | ±0.2%~±0.3% | ±0.2%~±0.3% | ±0.2%~±0.3% |

| Stability of Beam Current | ±0.2%~±0.3% | ±0.2%~±0.3% | ±0.2%~±0.3% | ±0.2%~±0.3% |

| Stability of Focusing Current | ±0.1% | ±0.1% | ±0.1% | ±0.1% |

Small Space

Fast Welding Speed and Strong Penetration

Fast Welding Speed and Strong Penetration

Adjustable workpiece position, real-time monitoring of welding

Application

Aviation, aerospace, nuclear energy utilizing industry, large steel plants, shipbuilding industries, etc..

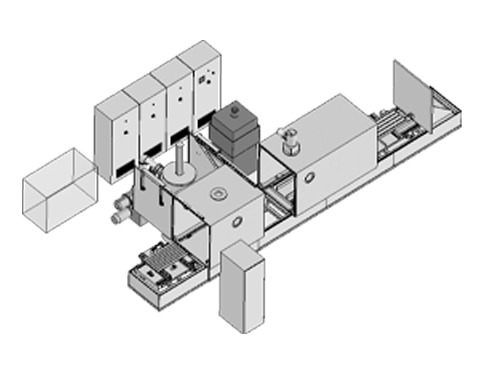

1. The model is with adjustable parameters and options for dual-axis or triple-axis linkage. The chamber volume depends on the dimensions of the workpiece, the required moving range, the process, and any special requirements.

2. The equipment is available in a basic standard model with PLC (Programmable Logic Controller) control and a precision CNC (Computer Numerical Control) model.

3. Electron beam welding parameters (such as high voltage, beam current, focusing, configuration, and instructions) and mechanical movement axis parameters (the movement trajectory and speed of the X, Y, and Z axes) can all be controlled via CNC programming.

4. The basic configuration of the equipment includes an X/Y linear worktable and a rotary worktable mechanical motion system.

5. The mechanical system has good strength and high rigidity, providing precise positioning accuracy and repeatability for both linear and rotational movements.

6. It features manual and automatic teaching functions, hand-pulse stepping, and programmed automatic operation controls. Additionally, the equipment includes various protection features such as flow monitoring, limit switches, alarms, and safety interlocks.

Technical Advantages

When welding with a vacuum electron beam welding machine, the energy density is high (about 108 watts/cm2), resulting in a high depth-to-width ratio of the weld seam and a small heat-affected zone. There is no need for filler metal, and it offers a high welding speed for high-quality industrial products, allowing for the one-time penetration of thick materials. Welding under vacuum conditions effectively prevents oxidation of the workpiece during the welding process. It provides high reliability and repeatability, with a wide range of adjustable process parameters and strong adaptability for welding a variety of materials.

Technical Characteristics

Specialized high-energy-density direct-heated electron gun with advanced electron-optical performance.

20kHz high-frequency high-voltage power supply, featuring rapid beam cutoff control and quick shutdown protection.

Advanced CNC numerical control for electron beam parameters and mechanical movements.

Vacuum system incorporates products from well-known domestic and international brands, ensuring high vacuum efficiency.

Modular design and manufacturing, with high standardization and reliability.